-

Belt misalignment monitoring

Belt misalignment monitoringWith a 30 till 40% share of all company dust explosions, it’s easy to say that a bucket elevator is a dangerous installation with a real explosion risk. This can easily be prevented and damage can be limited with our range of belt misalignment systems for vertical and horizontal transportation at conveyor belts.

Belt misalignment monitoring -

Bearing temperature monitoring

Bearing temperature monitoring60% of the early malfunctioning bearings is caused by material fatigue as a consequence of continuous fluctuating pressures on the bearing its surface and the use of incorrect lubricants. Bearing monitoring sensors are able to detect damages in an early stage and prevent downtime and potential dust explosions.

Bearing temperature monitoring -

Speed monitoring

Speed monitoringTo detect belt slip in an early stage we offer several speed monitoring switches to make sure you are informed in time when the belt slips. They also safeguard applications from overspeed or underspeed.

Speed monitoring -

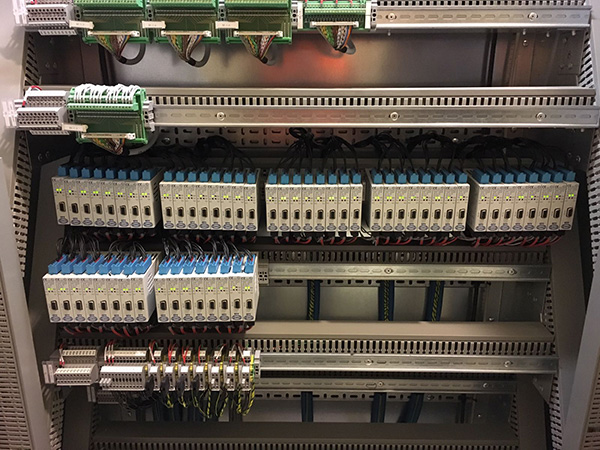

Controllers, indicators & transmitters

Controllers, indicators & transmittersFor a various range of process monitoring sensors Muller Beltex offers you the opportunity to select the correct controllers (ATEX), indicators and transmitters.

Controllers, indicators & transmitters -

Radar & level instruments

Radar & level instrumentsRadar and level instruments are generally used for cost efficient visualised level measurement of bulk goods. It supplies a continuous flow of reliable measuring data about the levels of the bulk goods in silo’s and small containers.

Radar & level instruments -

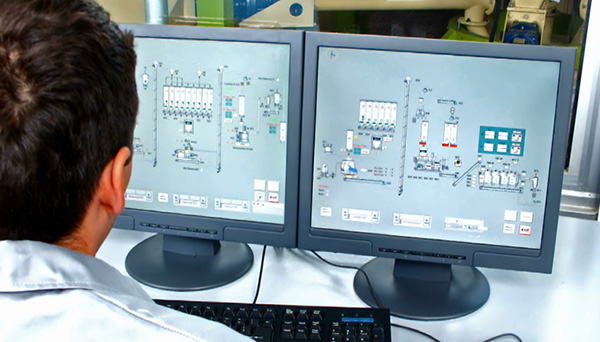

Data acquisition & SCADA systems

Data acquisition & SCADA systemsSupervisory Control And Data Acquisition, is collecting, forwarding, processing and the visualisation of monitoring signals of a various range of machines in huge industrial systems. We offer various solutions.

Data acquisition & SCADA systems -

Explosion vent panels & flameless vents

Explosion vent panels & flameless ventsExplosion pressure relief is the most natural version of constructive explosion protection. The over-pressure is deflated directly to prevent the protected amount of volume by damage of the pressure wave.

Explosion vent panels & flameless vents

To detect belt slip in an early stage we offer several speed monitoring switches to make sure you are informed in time when the belt slips. They also safeguard applications from overspeed or underspeed.

VARIOUS SPEED MONITORING SYSTEMS

Whirligig

Universal Shaft Sensor Mount

WG1A-BR – WG2A-BR – WG4A-BR – WG8A-BR – Universal Sensor

Universal Shaft Sensor Mount

EX II 2G 1D EE x m IIb T4 T 100°C zone 20, 21 & 22

Applications:

Fully guarded target for easy mounting of motion sensors. The ‘Whirligig’ three in one target/bracket/guard is suitable for all industry standard cylindrical or DIN style inductive sensors including our M100, M300 and M800 speed sensors.

The sensor bolts to the whirligig base plate and the complete assembly bolts to the machines shaft. The installation of speed sensors is now simple, reliable and fully guarded.

Shaft or machine vibration does not affect the performance of the sensor, as the whole assembly moves with the shaft.

Functions:

Fully Guarded Target for Easy Mounting of Motion Sensors

Suitable for all 4B sensors & other industry standard 18/30mm cylindrical sensors

Not affected by shaft or machine vibration

Easy Installation – Only Requires 1/2″ UNC Tapped Hole in the machine’s shaft

Optional Magnetic Connector “Magcon” simplifies mounting; no need to drill or tap the shaft

Options:

Whirligig: Target wheel ATEX approved

WG1A-BR: 1 Pulse per revolution

WG2A-BR: 2 Pulse per revolution

WG4A-BR: 4 Pulse per revolution

WG8A-BR: 8 Pulse per revolution

The Whirligig sensor can be connecting direct to a PLC or for increased security to an independent monitoring system such as the B400 ELITE, WATCHDOG ELITE or T500 Hotbus system.

M100 INDUCTIVE STOPSWITCH

M100 Inductive proximity Stopswitch

Detect Dangerous Underspeed Stop Conditions

M1001V10A – M100 Stopswitch 2-Wire

24-240 VAC/DC

Ex II 1D T100°C Zone 20

Applications:

The M100 Stopswitch is a simple inductive shaft speed-monitoring device. The self-contained unit has a single set point, which signals when the shaft has stopped rotating. It can be used for process control,motion detection and stopped shaft indication. An inductive sensing device located in the nose of the M100 enclosure will detect a metal target.

This target can be an existing bolt head or device attached to a shaft. The M100 Stopswitch requires no calibration and provides an output when the shaft has stopped rotating.

Functions:

Signals “stopped condition” on conveyors, bucket elevators, fans and all rotating machinery

Inductive proximity sensor which detects rotating metal target

Single trip set-point signal if no pulse is received within 4 seconds

Non-contacting & failsafe

Universal Voltage: 24-240V AC/DC

Start up delay: 4 seconds

“2-Wire”Technology: allows simple installation.

Microprocessor Accuracy

LED Indication

IP67 Protection: totally Sealed Construction

M18 x 1.0 ISO treaded body

M300 INDUCTIVE SLIPSWITCH

M300 Inductive proximity Slipswitch

Detect Dangerous Underspeed Slow Down Conditions

M3001V10AI – 2-Wire M300 Inductive proximity Slipswitch

24-240 VAC/DC

Ex II 1D T100°C Zone 20

M3005V10AI – 5-Wire M300 Inductive proximity Slipswitch

12-240 VDC / 24-240 VAC

Ex II 1D T100°C Zone 20

Applications:

The M300 Slipswitch is a simple inductive shaft speed monitoring device. The self-contained unit has a single set point, which signals when the shaft speed has dropped by 20% of normal running speed. It is used for detecting dangerous slow downs and underspeeds on conveyors, bucket elevators, airlocks, mixers, fans, grinders and many other machines.

An inductive sensing device located in the nose of the M300 enclosure will detect a metal target. This target can be an existing bolt head or device attached to a shaft. During installation the M300 is set to the normal machine shaft RPM by calibrating with the magnet provided. The internal microprocessor sets the underspeed output to operate at exactly 20% below normal machine shaft RPM, so users are able to use the M300 output for automatic shutdown during a dangerous underspeed or belt slip condition.

Functions:

Microprocessor controlled underspeed monitor

Signals underspeed for bucket elevators, conveyors and all rotating machinery

Inductive proximity sensor in 30mm diameter housing, which detects rotating metal target

Adjustable start-up delay-0 to 60 seconds

Magnetic Calibration of Microprocessor

-start-up delay

-normal running speed

Single set-point 20% underspeed

2 wire & 5 wire versions available

Non-contacting & failsafe

LED Indication

IP67 Protection

M800 INDUCTIVE SPEEDSWITCH

M800 Inductive proximity Speedswitch

Detect Dangerous Underspeed and Overspeed

M8001V1FC – Inductive proximity Speedswitch

110 VAC

CLASS 2 Div. 1 Groups E, F & G

M8001V2FC – Inductive proximity Speedswitch

220 VAC

CLASS 2 Div. 1 Groups E, F & G

M8001V4FC – Inductive proximity Speedswitch

24 VDC

Ex II 1D T100°C Zone 20

Toepassing:

The M800 Speed switch protects rotating equipment from dangerous underspeed conditions (elevator legs, conveyors, grinders, mixers, fans, etc.) The Inductive sensing devise, located in the nose of the M800 detects a rotating metal target on a shaft. If the machine speed falls by 10% or 20% below its nominal RPM, the monitor provides output signals for alarm and / or shutdown of the machinery.

Functies:

Microprocessor controlled speedswitch

Signals underspeed conditions for bucket elevators, conveyors and all rotating machinery

Dual set points –Alarmat10% underspeed; Stop at20% underspeed

DustProof and Watertight-IP67

Speed range -10 to 3600 PPM

Magneticcalibration of the micro-processor

-start-up delay

-normal running speed

User adjustablestart-up delay: 0-30 seconds

Inductive proximity sensor, in DIN style housing, which detects a rotating metal target

Non-contacting & failsafe

OVERVIEW ATEX PROCESS MONITORING SYSTEMS

Our stockholding strategy and top-quality product range allows us to always offer the right solution for your installation, anywhere in the world. Together with an comprehensive problem analysis and the right measures and design. Flexible & fast. Largely the result of our customers’ needs we have continuously been optimising our product range.

OUR OTHER COMPONENTS

WE ALSO OFFER ENGINEERING, ADVICE AND SUPERVISION SERVICES

Muller Beltex likes to share their knowledge as a consultant for your specific issue. Engineering, advice and supervision services to get your bulk handling and processing equipment running optimally. By involving us at an early stage, we can offer you the right solution based on our broad experience and know-how.