-

Belt misalignment monitoring

Belt misalignment monitoringWith a 30 till 40% share of all company dust explosions, it’s easy to say that a bucket elevator is a dangerous installation with a real explosion risk. This can easily be prevented and damage can be limited with our range of belt misalignment systems for vertical and horizontal transportation at conveyor belts.

Belt misalignment monitoring -

Bearing temperature monitoring

Bearing temperature monitoring60% of the early malfunctioning bearings is caused by material fatigue as a consequence of continuous fluctuating pressures on the bearing its surface and the use of incorrect lubricants. Bearing monitoring sensors are able to detect damages in an early stage and prevent downtime and potential dust explosions.

Bearing temperature monitoring -

Speed monitoring

Speed monitoringTo detect belt slip in an early stage we offer several speed monitoring switches to make sure you are informed in time when the belt slips. They also safeguard applications from overspeed or underspeed.

Speed monitoring -

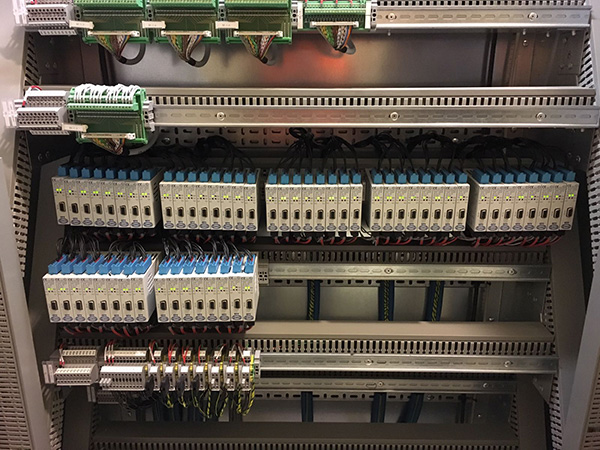

Controllers, indicators & transmitters

Controllers, indicators & transmittersFor a various range of process monitoring sensors Muller Beltex offers you the opportunity to select the correct controllers (ATEX), indicators and transmitters.

Controllers, indicators & transmitters -

Radar & level instruments

Radar & level instrumentsRadar and level instruments are generally used for cost efficient visualised level measurement of bulk goods. It supplies a continuous flow of reliable measuring data about the levels of the bulk goods in silo’s and small containers.

Radar & level instruments -

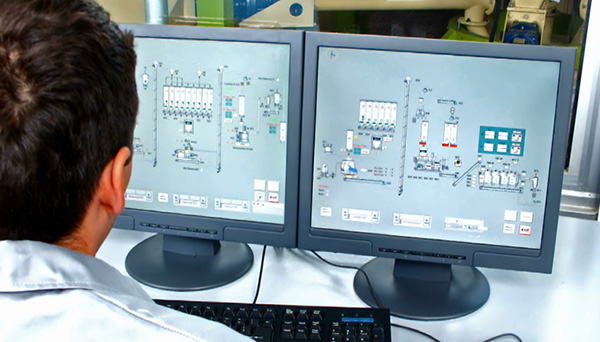

Data acquisition & SCADA systems

Data acquisition & SCADA systemsSupervisory Control And Data Acquisition, is collecting, forwarding, processing and the visualisation of monitoring signals of a various range of machines in huge industrial systems. We offer various solutions.

Data acquisition & SCADA systems -

Explosion vent panels & flameless vents

Explosion vent panels & flameless ventsExplosion pressure relief is the most natural version of constructive explosion protection. The over-pressure is deflated directly to prevent the protected amount of volume by damage of the pressure wave.

Explosion vent panels & flameless vents

With a 30-40% share of all company dust explosions, it’s easy to consider bucket elevators as an ‘dangerous’ installation with a realistic chance for explosion. Researcg shows that these explosions and damages can easily be limited with various belt misalignment monitoring systems for horizontal and vertical transport. Customers currently prefer our Rub-Block because it detects misalignment based on temperature friction.

BELT MISALIGNMENT MONITORING – SENSORS FOR CONVEYORS AND BUCKET ELEVATORS

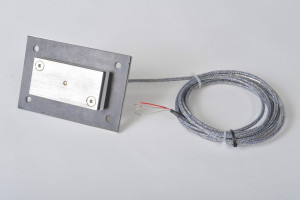

Our own product Rub-Block with a PT100 temperature sensor is designed to report the misalignment of a conveyor belt or elevator belt. The advantage of the Rub-Block is the fact that it will send a continuous output signal to the PLC. We also offer other brands belt misalignment monitoring solutions such as the well-known product Watchdog produced by 4B. Please involve us at an early stage so we can offer you the right solution for your specific issue.

RUB-BLOCK ,TYPE RB200DN RECTANGULAR WITH PT100 SENSOR

The Rub-Block with a PT100 temperature sensor is designed to report a belt misalignment of an elevator, conveyor and a HI-rollers. The RB200DN can be used for elevators from 12 meters height. The advantage of the Rub-Block is the fact that it will send a continuous output signal to the PLC. The Rub-Block emits a permanent standby signal. If such a signal is absent, the reason for this must be investigated and if so required the PT100 sensor must be replaced. As long as the Rub-Block emits a standby signal, it will also emit an emergency contact signal caused by its temperature rising, as soon as a belt touches it.

Off-tracking belts running into the side of conveyor equipment will cause friction, which may cause damage to the belt, and may generate heat, fire, or a dust explosion. The RB200DN is very easy to install, it will be fitted on both sides of a conveyor or elevatorbelt. Once the belt off-tracks and runs onto the brass plate of the Rub-Block, it will create friction and the temperature of the Rub-Block brass plate increases.

Technical information:

Pt100 sensor: 4-core cable with a length of 3 meters. Probe (PT100) length 60mm, made of brass and partly stainless steel.

Including rectangular NBR rubber seal (150mm x 100mm)

ATEX Classification version (Ex-i)

III 1/2 D Ex ia IIIC TX Da/Db, II 1/2 G Ex ia IIC T6..T1 Ga/Gb -40°C tot 185°C

Certificate number: IBExU13ATEX1079X

RUB-BLOCK WITH CONDUIT ENTRY, TYPE RB200DN RECTANGULAR WITH PT100 SENSOR

The Rub-Block with a PT100 temperature sensor is designed to report a belt misalignment of an elevator, conveyor and a HI-rollers. The RB200DN can be used for elevators from 12 meters height. The advantage of the Rub-Block is the fact that it will send a continuous output signal to the PLC. The Rub-Block emits a permanent standby signal. If such a signal is absent, the reason for this must be investigated and if so required the PT100 sensor must be replaced. As long as the Rub-Block emits a standby signal, it will also emit an emergency contact signal caused by its temperature rising, as soon as a belt touches it.

CSA CLASS 2 DIV-1

RUB-BLOCK, TYPE RB100DN WITH PT100 SENSOR

The Rub-Block with a PT100 temperature sensor is designed to report a belt misalignment of an elevator, conveyor and a HI-rollers. The RB100DN can be used for elevators till 12 meters height. The advantage of the Rub-Block is the fact that it will send a continuous output signal to the PLC. The Rub-Block emits a permanent standby signal. If such a signal is absent, the reason for this must be investigated and if so required the PT100 sensor must be replaced. As long as the Rub-Block emits a standby signal, it will also emit an emergency contact signal caused by its temperature rising, as soon as a belt touches it.

Off-tracking belts running into the side of conveyor equipment will cause friction, which may cause damage to the belt, and may generate heat, fire, or a dust explosion. The RB100DN is very easy to install, it will be fitted on both sides of a conveyor or elevatorbelt. Once the belt off-tracks and runs onto the brass plate of the Rub-Block, it will create friction and the temperature of the Rub-Block brass plate increases.

Technical information:

Pt100 sensor: 4-core cable with a length of 3 meters. Probe (PT100) length 60mm, made of brass and partly stainless steel.

Including round NBR rubber seal (Ø92mm x 2mm)

ATEX Classification version (Ex-i)

III 1/2 D Ex ia IIIC TX Da/Db, II 1/2 G Ex ia IIC T6..T1 Ga/Gb -40°C tot 185°C

Certificate number: IBExU13ATEX1079X

RUB-BLOCK WITH CONDUIT ENTRY, TYPE RB100DN ROUND WITH PT100 SENSOR

The Rub-Block with a PT100 temperature sensor is designed to report a belt misalignment of an elevator, conveyor and a HI-rollers. The RB100DN can be used for elevators till 12 meters height. The advantage of the Rub-Block is the fact that it will send a continuous output signal to the PLC. The Rub-Block emits a permanent standby signal. If such a signal is absent, the reason for this must be investigated and if so required the PT100 sensor must be replaced. As long as the Rub-Block emits a standby signal, it will also emit an emergency contact signal caused by its temperature rising, as soon as a belt touches it.

CSA CLASS 2 DIV-1

Certificate number:

RUB-BLOCK RVS, RECTANGULAR, TYPE RVSRB200DN WITH PT100 SENSOR

The RVS Rub-Block with a PT100 temperature sensor is designed to report a belt misalignment of an elevator, conveyor and a HI-rollers. The RVS RB200DN can be used for elevators from 12 meters height. The advantage of the Rub-Block is the fact that it will send a continuous output signal to the PLC. The RVS Rub-Block emits a permanent standby signal. If such a signal is absent, the reason for this must be investigated and if so required the PT100 sensor must be replaced. As long as the RVS Rub-Block emits a standby signal, it will also emit an emergency contact signal caused by its temperature rising, as soon as a belt touches it.

Off-tracking belts running into the side of conveyor equipment will cause friction, which may cause damage to the belt, and may generate heat, fire, or a dust explosion. The RVS RB200DN is very easy to install, it will be fitted on both sides of a conveyor or elevatorbelt. Once the belt off-tracks and runs onto the brass plate of the Rub-Block, it will create friction and the temperature of the Rub-Block brass plate increases.

Technical information:

Pt100 sensor: 4-core cable with a length of 3 meters. Probe (PT100) length 60mm, made of stainless steel.

Including rectangular NBR rubber seal (150mm x 100mm)

ATEX Classification version (Ex-i)

III 1/2 D Ex ia IIIC TX Da/Db, II 1/2 G Ex ia IIC T6..T1 Ga/Gb -40°C tot 185°C

Certificate number: IBExU13ATEX1079X

RUB-BLOCK RVS, ROUND, TYPE RVSRB100DN WITH PT100 SENSOR

The RVS Rub-Block with a PT100 temperature sensor is designed to report a belt misalignment of an elevator, conveyor and a HI-rollers. The RVS RB100DN can be used for elevators up to 12 meters height. The advantage of the Rub-Block is the fact that it will send a continuous output signal to the PLC. The RVS Rub-Block emits a permanent standby signal. If such a signal is absent, the reason for this must be investigated and if so required the PT100 sensor must be replaced. As long as the RVS Rub-Block emits a standby signal, it will also emit an emergency contact signal caused by its temperature rising, as soon as a belt touches it.

Off-tracking belts running into the side of conveyor equipment will cause friction, which may cause damage to the belt, and may generate heat, fire, or a dust explosion. The RVS RB100DN is very easy to install, it will be fitted on both sides of a conveyor or elevatorbelt. Once the belt off-tracks and runs onto the brass plate of the Rub-Block, it will create friction and the temperature of the Rub-Block brass plate increases.

Technical information:

Pt100 sensor: 4-core cable with a length of 3 meters. Probe (PT100) length 60mm, made of stainless steel.

Including round NBR rubber seal

ATEX Classification version (Ex-i)

III 1/2 D Ex ia IIIC TX Da/Db, II 1/2 G Ex ia IIC T6..T1 Ga/Gb -40°C tot 185°C

Certificate number: IBExU13ATEX1079X

OVERVIEW ATEX PROCESS MONITORING SYSTEMS

Our stockholding strategy and top-quality product range allows us to always offer the right solution for your installation, anywhere in the world. Together with an comprehensive problem analysis and the right measures and design. Flexible & fast. Largely the result of our customers’ needs we have continuously been optimising our product range.

OUR OTHER COMPONENTS

WE ALSO OFFER ENGINEERING, ADVICE AND SUPERVISION SERVICES

Muller Beltex likes to share their knowledge as a consultant for your specific issue. Engineering, advice and supervision services to get your bulk handling and processing equipment running optimally. By involving us at an early stage, we can offer you the right solution based on our broad experience and know-how.