Many concrete mixing plants perform maintenance on their installations during the construction holiday. They aim to bring their plants back up to date so as to optimise performance in terms of capacity, as well as the service life of wear components.

Muller Beltex is regularly involved in this and first conducts an on-site inspection that in detail reviews the product overshoot area’s, chutes and bunkers, as well as the abrasion-resistant Kryptane® liners to determine whether it is due for replacement. The result is an inspection report with recommendations that also considers urgencies and the available budget.

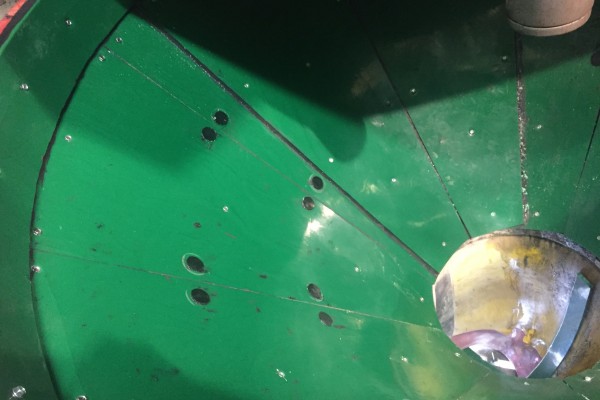

That the elevator becomes dirty is a common occurrence, but there also is a great deal of wear and tear on the:

– Steel elevator parts

– Bucket elevator belt

– Elevator buckets

– Elevator’s inlet and outlet

– Pulleys and pulley lagging

Based on the inspection report, Muller Beltex looks after the maintenance, assembly and installation, archives the documentation in the proper files and ensures that the installation once again operates optimally. For additional information about our services, review our brochures by clicking on the button below or contact one of our specialists. They are happy to provide you with additional information.

GO TO BROCHURES