-

Elevator belts

Elevator beltsFrom experience we know which elevator components and moving parts are subjected to the most wear. What lies at the heart of optimal and safe bulk processing is the elevator belt: to us, the elevator belt is the key. A good quality elevator belt is crucial and can be offered with Polysur.

Elevator belts -

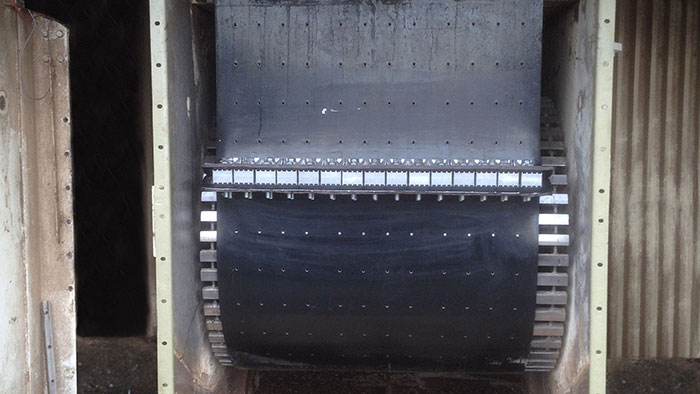

Elevator belt fasteners

Elevator belt fastenersThe connection is the weakers link in an elevator belt, which is why belt fasteners deserve special attention. We supply various belt fasteners for connecting belts with specially woven polyester/polyamide plies (EP) or steel fabric reinforcements.

Elevator belt fasteners -

Elevator buckets

Elevator bucketsWe have an extensive product range of elevator buckets for light, medium and heavy circumstances so we can always offer a fitting solution.

Elevator buckets -

Elevator bolts

Elevator boltsElevator buckets are fitted using specially designed fastening hardware.

Elevator bolts -

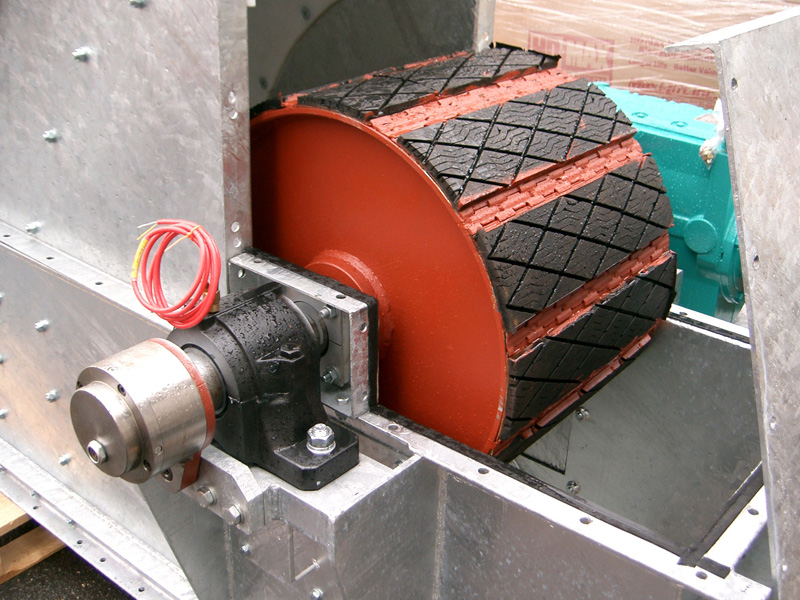

Drive and return pulleys

Drive and return pulleysFrom drive pulleys and cage pulleys to wing pulleys: our engineers take care of the entire process, from drawings to implementation providing the right solution for your elevator belt.

Drive and return pulleys -

Pulley lagging

Pulley laggingA good pulley lagging is absolutely essential for friction between the elevator belt and the drive pulley. A good lagging prevents the elevator belt from slipping and reduces wear.

Pulley lagging

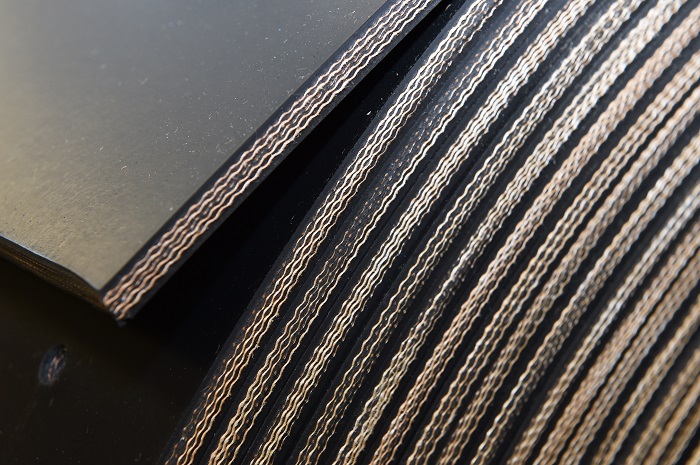

What lies at the heart of optimal and safe bulk processing is the elevatorbelt: to us, the elevator belt is the key. This is the heart of the machine and, when running, the belt is subjected to various loads. Choosing a good quality elevator belt is crucial when it comes to preventing costly downtime and optimum production results. Our own developed Polysur® elevator belts, reinforced with specially woven polyester/polyamide plies (EP) or steel fabric reinforcements, are specially manufactured for use in elevators and can be supplied with bolt holes for elevator buckets.

Our extensive product range with supplementary components offers a high-quality package that prevents wear and keeps maintenance to a minimum.

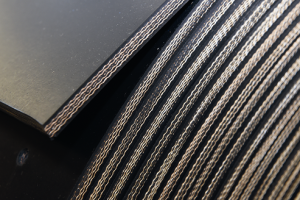

POLYSUR FERRO STEEL FABRIC REINFORCED ELEVATOR BELT

Significant lift heights and heavy elevator buckets require an extremely strong transverse belt construction. This can be achieved with Fleximat® steel fabric reinforcement, a specially produced fabric comprising length cords and cross cords which are bound together to form a unified structure. This rubber elevator belt is ideal for high temperature applications up to max. + 150˚C.

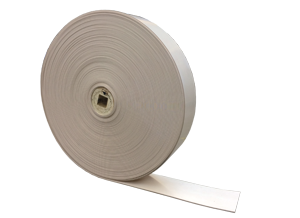

POLYSUR TYPE 272 NBR-FDA WHITE FOOD-GRADE QUALITY

POLYSUR TYPE 274 SBR STANDARD QUALITY

POLYSUR TYPE 275 NBR OIL- AND FAT RESISTANT QUALITY

POLYSUR TYPE 275-K NBR OIL- AND FAT RESISTANT FLAME-RETARDANT QUALITY

This belt quality is very good oil and fat resistant and is specially designed for use in combination with agricultural products and animal feed. This elevator belt is suitable for conveying products with vegetable and animal oils and fats. This elevator belt quality is also flame-retardant according to ISO 340 (=DIN -K-).

POLYSUR TYPE 276 NBR OIL- AND FAT RESISTANT QUALITY

These nitrile elevator belts are specially tailored to applications in the agro-industry and animal feed industry. This quality is excellent oil and fat resistant and therefore offers the highest possible resistance against vegetable and animal oils and fats, but also mineral oils. Type 276 has proven itself in elevators that run 24/7 and transport products such as rapeseed, soybeans and sunflower seeds.

POLYSUR TYPE 278 NBR HOT OIL QUALITY

These elevator belts have a unique belt quality specifically designed to withstand a combination of fat and higher process temperatures in operating conditions with a high level of humidity (water vapour, fat and oils). By its special construction this belt quality achieves a longer service life under the previously mentioned circumstances.

POLYSUR TYPE T150 HEAT RESISTANT QUALITY

These elevator belts are applied in elevators that transport products with a constant temperature up to max. + 130°C. With its standard thicker rubber coating, the fabric mesh is well isolated against higher temperatures and prevents unnecessary stretching of the belt. The combination with a highly heat-resistant rubber, which remains flexible and has less rapid curing, makes this belt highly sought after when transporting cement and fly ash.

OVERVIEW COMPONENTS FOR ELEVATORS

Our stockholding strategy and top-quality product range allows us to always offer the right solution for elevator. Largely the result of our customers’ needs we have continuously been optimising our product range.

OUR OTHER COMPONENTS

WE ALSO OFFER ENGINEERING, ADVICE AND SUPERVISION SERVICES

Muller Beltex likes to share their knowledge as a consultant for your specific issue. Engineering, advice and supervision services to get your bulk handling and processing equipment running optimally. By involving us at an early stage, we can offer you the right solution based on our broad experience and know-how.