The widely applicable product brand Kryptane® offers a solution for every wear issue, preventing costly downtime These polyurethane liners are manufactured based on a patented chemical formula, which creates extra cross links between the molecules of the polyurethane which makes Kryptane® unsurpassed in elasticity and abrasion-resistance. Kryptile® offers a solution for sharp and coarse product while the product brand Blue-Ox® is most suitable for agricultural applications with light to medium wear. For fixing and finishing Muller Beltex offers a range of possibilities.

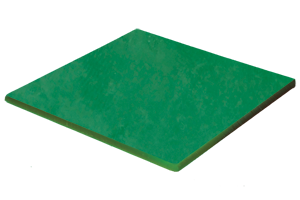

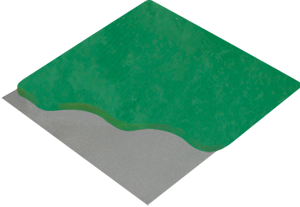

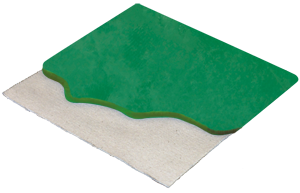

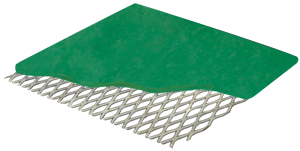

KRYPTANE GREEN 83° SHORE A

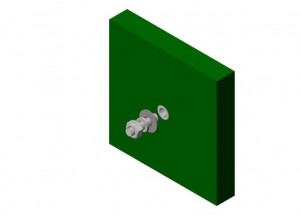

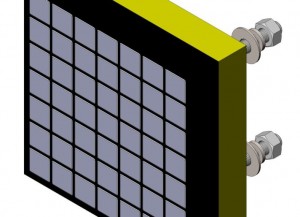

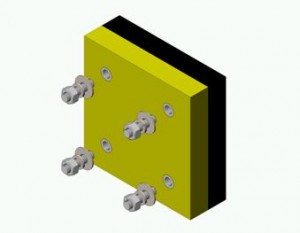

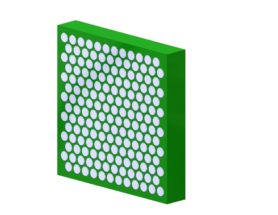

High-resistance polyurethane against strong sliding, cutting and impact wear with rough product up to 50 mm lump size. Mounting is possible using adhesive or various types of bolts, and it is available with a fabric layer (image three) for adhesive fixing. For fixing with bolts, stretched metal (image four) or a solid steel base (image two) is available. A Muller Beltex specialist will be glad to advise you on fixing and finishing.

KRYPTANE RED 80° AND 90° SHORE A

KRYPTANE YELLOW 59° SHORE A

KRYPTANE BLACK 93° SHORE A

BLUE-OX BLUE 85° SHORE A

FRAS ANTISTATIC POLYURETHANE LINER

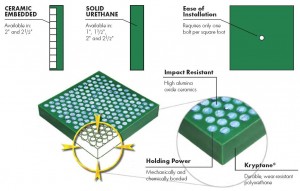

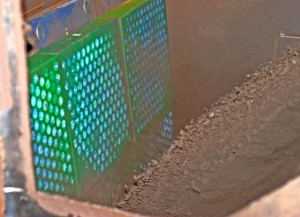

KRYPTILE CERAMIC POLYURETHANE LINERS

Kryptile is the solution for aggressive applications. Kryptile ceramic liners combine the wear resistance of high alumina oxide ceramic with the impact resistance of Kryptane® polyurethane. Kryptile liners are all custom designed to the shape of your chute, bin or hopper, eliminating the need to cut or fit the liners in the field and ensuring a perfect fit every time. There are also standard panels available sizes 300 x 300 mm. with a steel plate in it with a welded nut for fast mounting in the field.

REDI-LINERS IMPACT PANELS

Redi-Liner™ Modular Panels

Redi-Liner is easy to install and will outlast most any other wear product available today. With the option of both solid and ceramic-embedded urethane in one area, the interchangeability makes for an easy solution in your toughest wear spots.Quick change-out allows for limited downtime and and easily manages your hot spot repairs.

Kryptile KT is the original ceramic hextile liner. The hextile formation is closely gapped to provide superior sliding abrasion resistance in high fines applications, wet or dry. Kryptile KT is generally not recommended for applications where there is impact; it is for slide abrasion only.

Kryptile KC works well in virtually all applications. Kryptile KC is available in liners at least 11 ∕4” (32 mm) thick. Kryptile KC is generally recommended for applications with 6” (152mm) minus rock dropping a maximum of 4 feet (1.22 meters).

Kryptile KS is specifically designed for aggressive applications with high impact and large rock. Kryptile KS is generally recommended for applications with 10” (254mm) minus rock dropping from a maximum of 6 feet (1.83 meters).

Kryptile KH is our ceramic cube liner. Kryptile KH is available in liners at least 2” (51 mm) thick. Kryptile KH is generally recommended for applications with 15” (381mm) minus rock dropping from a maximum of 8-10+ feet (2.44 – 3.05+ meters).

KRYPTANE KS03 DUO

FIXING MATERIALS

Kryptane® is easy to process and install as it is relatively light and flexible. Mounting is possible using adhesive or various types of bolts, and it is available with a fabric layer for adhesive fixing. For fixing with bolts, stretched metal or a solid steel base is available. A Muller Beltex specialist will be glad to advise you on fixing and finishing.

OUR OTHER COMPONENTS

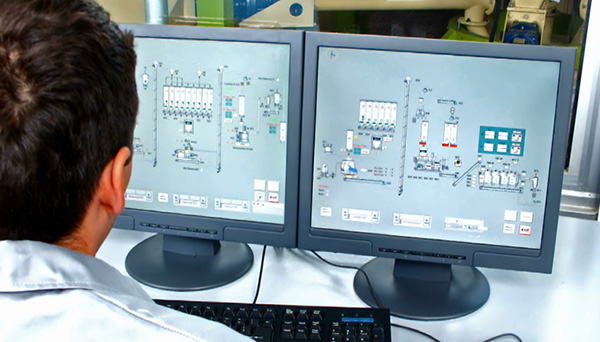

WE ALSO OFFER ENGINEERING, ADVICE AND SUPERVISION SERVICES

Muller Beltex likes to share their knowledge as a consultant for your specific issue. Engineering, advice and supervision services to get your bulk handling and processing equipment running optimally. By involving us at an early stage, we can offer you the right solution based on our broad experience and know-how.