The demand for safety in and around the elevator is an issue subject to adaptations of the relative applicable directives. Statistics describe the elevator as one of the most hazardous pieces of equipment because of real risk of explosion. 30-40 percent of dust explosions involve elevators. An enclosed system combined with the conveying of flammable bulk material, oxygen and possible ignition sources explain this risk of explosion. Research has shown that this can be prevented and damage can be effectively limited with various preventive and curative process monitoring systems.

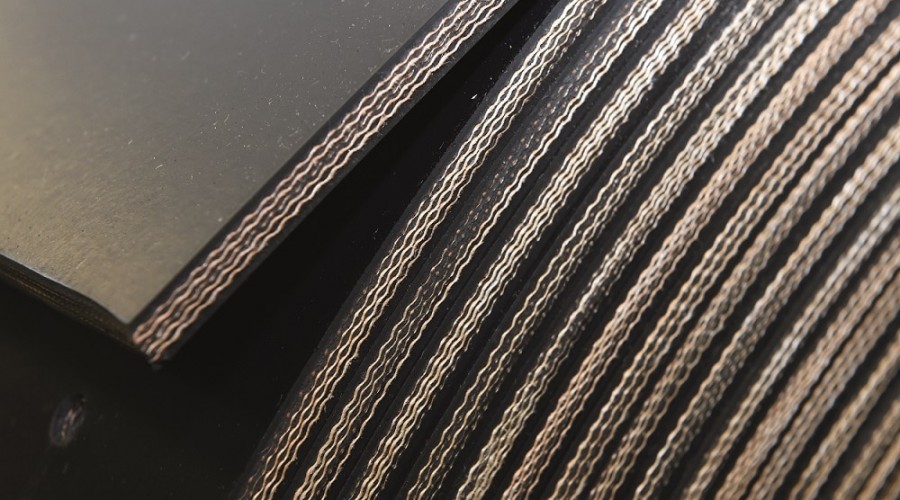

To prevent the spread of fire and further limit the risk of explosion one can opt for an antistatic ISO 284 and flame-retardant ISO 340 (= DIN–K-) elevator belt. In addition to our Polysur® types 272 and 278, which are already flame-retardant and own other properties, we’ve extended our range of conventional elevator belts with an extra property: flame-retardant in accordance with ISO 340 and added to our range of Polysur® elevator belts named “Polysur® type 275-K”. Click on the button below for the technical datasheet and the antistatic (ISO 284) and flame-retardant declaration (ISO 340).

Download technical datasheet

Download antistatic & flame-retardant statement