How does this contribute to reducing your cost?

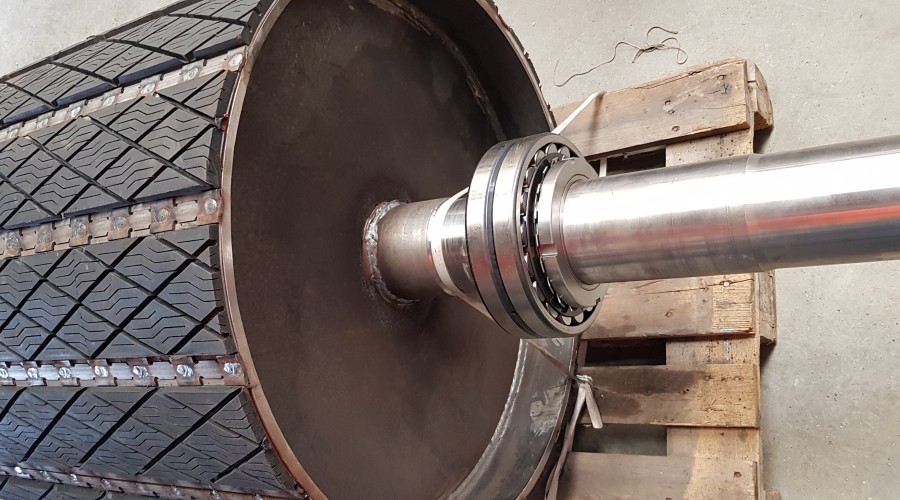

To us, the elevator belt is the key in combination with a highly critical part, the elevator belt fastener. The elevator belt is the most critical item in a bucket elevator and when operating subjected to various conditions. Heavy duty industry demands the utmost performance of components used in elevators. Higher loads, longer center distances, higher temperatures and tough applications require specific knowledge, a different approach and innovative solutions.

Wear in the elevator

The elevator belt is the heart of the elevator. All the additional items that will be fitted on the belt like elevator buckets, bolts and belt fasteners are in sense foreign objects to the belt, which in the long run could result into stress and wear, due to the pressure of these parts while running over the pulleys. Every elevator belt will first develop wear and tear in those areas where these foreign objects are attached to the belt, whether the application is hot or cold. To avoid such premature wear, in particular in the cement industry, the belt should have a maximum temperature resistance and all items attached to the belt should be as light as possible. Once a belt is aging due to affection of heat, the wear and tear due to the attached objects will be more severe, for the reason that the rubber loses its strength and elasticity.

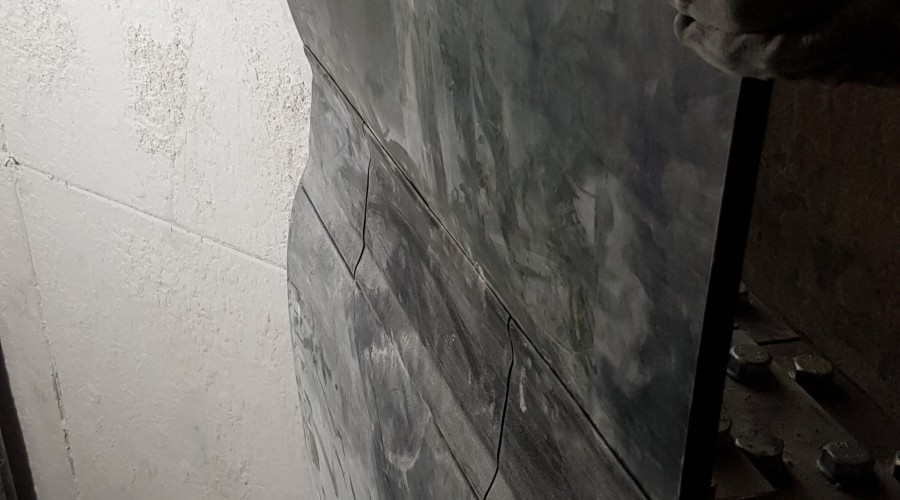

The joint area between the two elevator belt ends is the first area where wear will take place. The exact location of the wear is the area where the fastener comes in contact with the drive pulley. In the sketch below the exact location is indicated by a red arrow. The unique removable rubber wear part that is fitted on the aluminum wedge section of the Polysur® Solid belt fastener prevents the belt from wear and extends durability.

Several bucket elevator manufacturers and end-users apply very heavy components and install belt fasteners which are designed for single irrevocable use. If for example maintenance is required where it is inevitable having to open the belt, and the belt fastener cannot be used in the same area and belt length is lost to fit a clamp again, it will be expensive and unwelcome exercise.

Our fasteners are designed as light as possible and consist of multiple sections across the belt width, so not one single beam across the full width of the belt. The effect of the centrifugal forces on the clamp when passing the pulleys should not be underestimated. The design of the clamp should be so that it supports the belt on the pulley surface and thus prevent wear to the belt.

The projection (=horizontal dimension) of our Polysur® Solid belt fastener should remain within the projection of the buckets, as otherwise it may result into a bucket getting caught by the discharge chute.

Design belt fastener

In the past, Muller Beltex has done a lot of research on shortcomings of existing belt fasteners that are being used on steel cord elevator belts. During our inspections on many bucket elevators constructed by OEM’s, we have studied all the information and have developed our Polysur® Solid belt fastener.

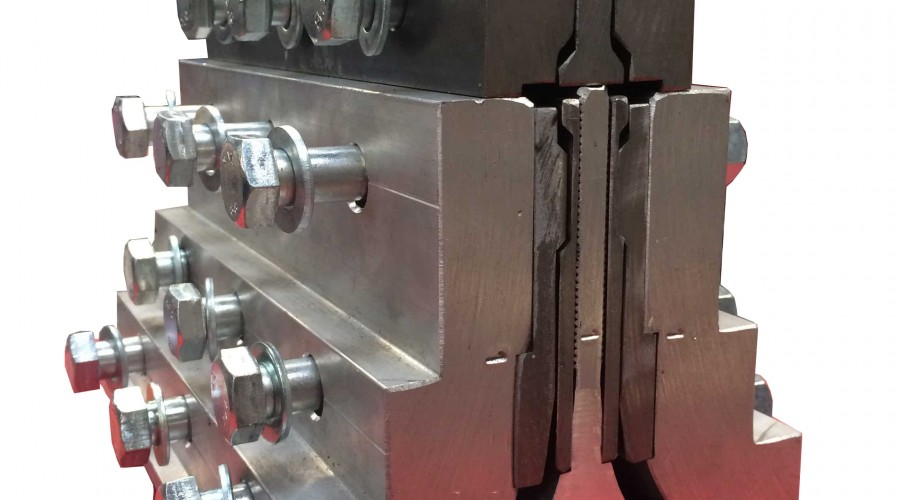

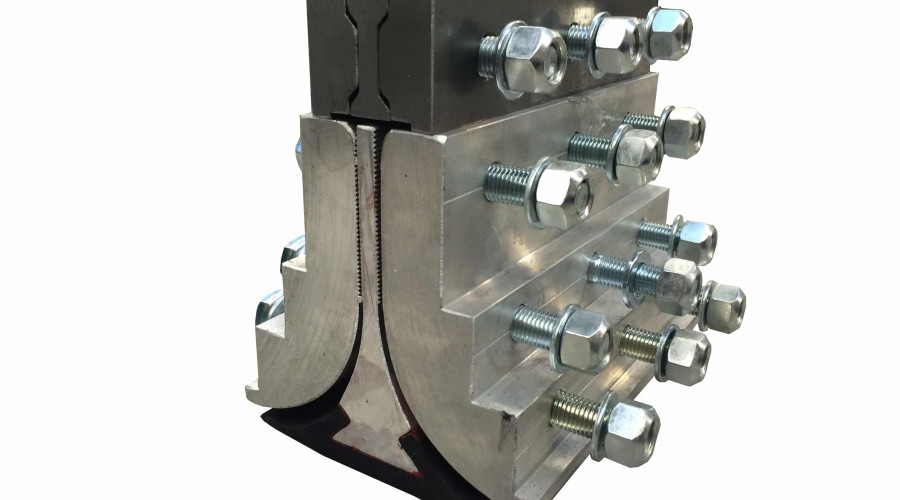

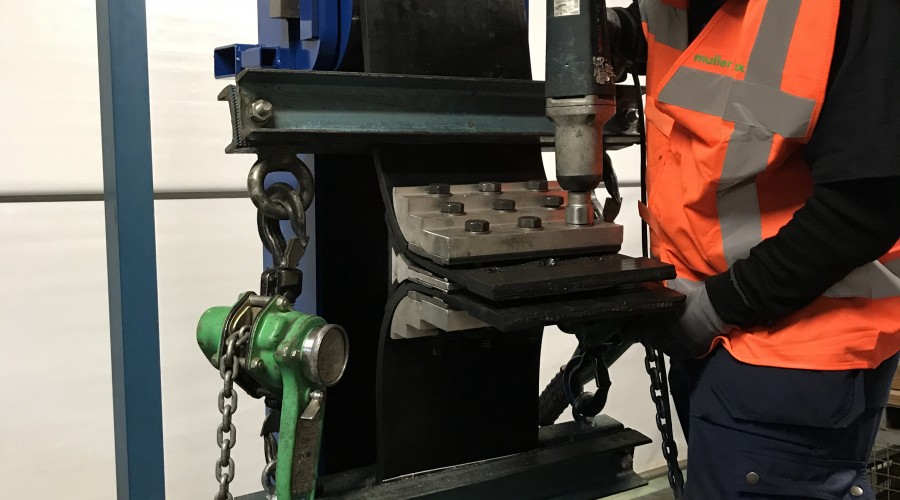

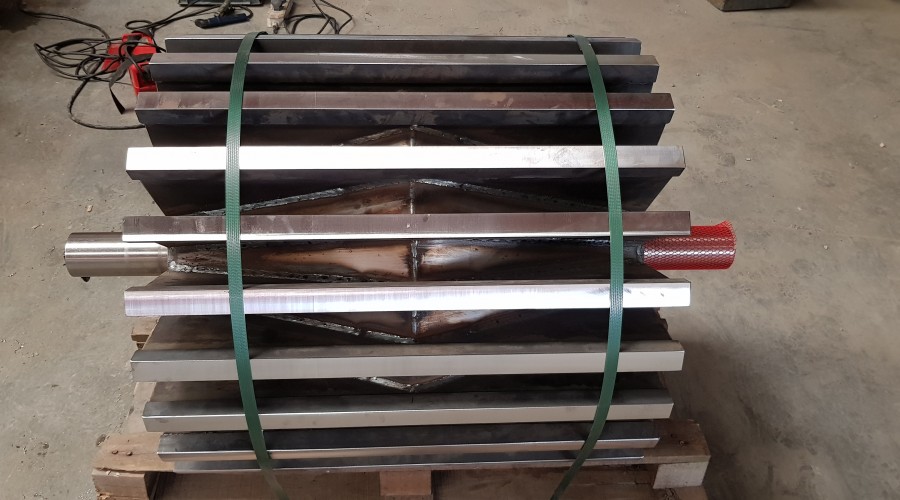

Steel cord elevator belts, such as our Polysur® Ferro steel cord elevator belts, are preferably made endless with the matching designed Polysur® Solid belt fastener. This is a heavy duty mechanical clamping device with a three piece construction made of a high quality aluminum and an additional vice-grip section. The working is based on clamping forces and friction. The belt ends are bend 90° with a radius of 75 mm. This angle and radius of the belt fastener results into a maximum allowed specification without loss of strength and a negative effect on the steelcords.

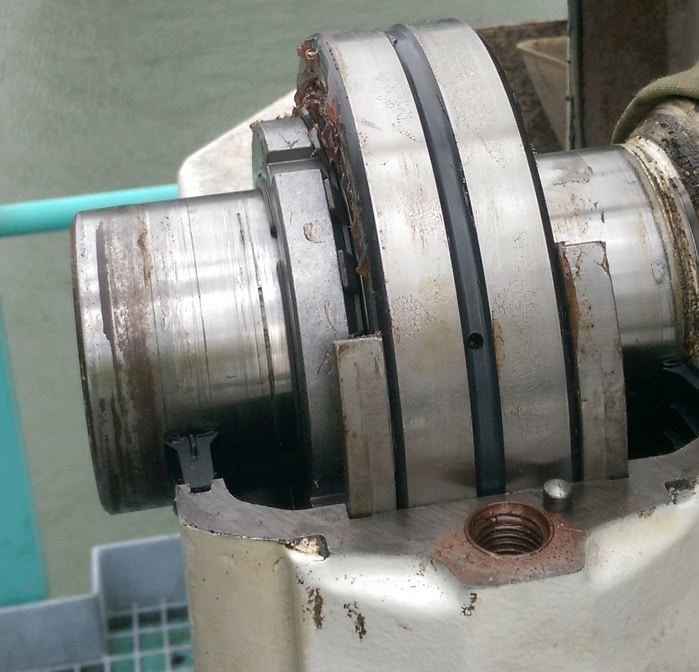

The Polysur® Solid belt fastener is manufactured from a high-grade aluminum extruded product. The belt fastener is composed of two outers and in between a central wedge. The outers are at the inner side executed with a grip surface in order to increase the frictional resistance.

The wedge ensures the guiding and protection of the elevator belt and procures an extra protection surface as well. The wedge is manufactured from rubber and is replaceable. To make sure that the belt fastener runs smoothly over the pulley, with less vibration, there has been assembled on top of the wedge a part of high heat rubber profile, which is unique in the industry. Moreover, this central rubberized section ensures the safe use of different belt constructions with different belt thicknesses.

This critical part is suitable for temperatures up to 150° C. In case of temperatures exceeding 150° the rubber segment can be replaced by an aluminum segment.

The assembled rubber wedge is considered a critical part, since there will be a lot of pressure and friction inflicted on the belt every time it is running over the pulley.

Because the Polysur® Solid belt fastener is made of high-quality aluminum, it is non-corroding and non-sparking in the cement industry.

The vice-part is the heart of the Polysur® Solid belt fastener. The vice-part is produced in steel or aluminum and is fitted behind the Polysur® Solid belt fastener. The vice-part is securely placed, unlike the belt fastener, not on the rubber belt surface but holds the steel cords of the elevator belt and therefore the rubber covers and weft cords should be omitted. If this additional part would not be applied, the warp cords could shift and could possibly be pulled out.

The three parts of the belt fastener are provided with bolt holes. The position and the number of bolt holes can either be calculated by Muller Beltex engineers through a calculation program, knowing exactly how much safety the clamp provides related to the belt strength, or determined by our customers engineers.

Muller Beltex determines the appropriate type of the Polysur® Solid belt fastener according to a number of parameters. The belt fastener can be produced in two or more sections depending on the belt’s width and the crowning of the drive pulley. The total width of the belt fastener has to be approximately 15 mm less compared to the width of the full elevator belt.

The belt fastener has a standard projection (=horizontal dimension) of 150 mm.

For belt constructions ranging up to 2.000 N/mm, the Polysur® Solid belt fastener with single steel vice-part can be used. From 2.500 up to 2.750 N/mm our Polysur® Solid belt fastener with a double steel vice-part should be applied. From 3.000 up to 4.000 N/mm our Polysur® Solid belt fastener with a triple steel vice-part is recommended.

Shortest possible downtime

The big advantage of the Polysur® Solid belt fastener is that you can reuse it after disassembly. Steel cord belt fasteners produced by other suppliers are often locked (single use only). In many cases one have to tighten the steel cords together and after a template has to be put around the cords which are tightened together and a hot epoxy is casted in the template to seal the belt fastener. Again, when maintenance is required on one of the pulleys for example, the belt has to be cut and the belt fastener cannot be reused and has to be considered as an unnecessary loss. It would be best if the belt fastener could be reused again, since it is an expensive component which should be durable. With the Polysur® Solid belt fastener you only have to consider to replace the bolts, washers and nuts in the clamp, and if worn, the rubber wedge section. We find this a more economical and durable method.

We do not only provide our products and services to OEM’s and specialists, but also supply directly to end-users and assist with the fitting of the belt and components on site. The end customer is not only looking for a quality belt that he can depend on, but also wants to save downtime on maintenance. The longest operation time is required, so that it will reduce maintenance cost and have the shortest possible downtime. The installation has to run and by reusing a belt fastener which prevents wear on the elevator belt as well, the end user’s total cost of ownership will be improved.